Advanced Coating Technology Reserch Center, Department of Electronics and Manufacturing, AIST

Research TeamSERVICE&PRODUCTS

Fine Powder Spray Coating Team|Photo-assisted Coating Team|Energy Conversion and Storage Materials Team |Green Device Materials Team

Fine Powder Spray Coating Team

<Research outline>

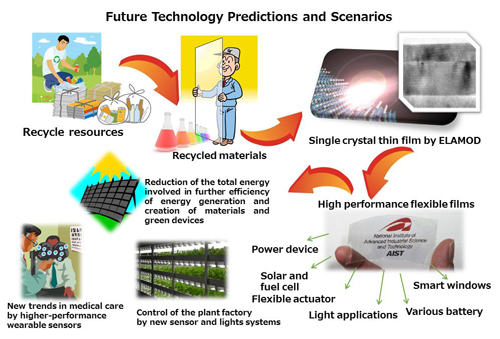

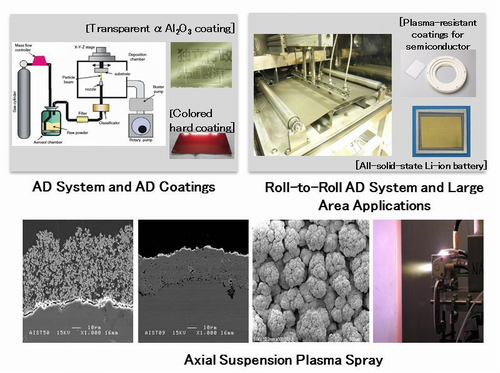

The ceramic coating can impart various surface functions to the member surface such as electrical, optical, abrasion resistance, corrosion resistance and heat resistance. It is expected to expand applications in a wide range of fields such as electronics, automobile and aircraft, energy and medical related members. But in general, high temperature heat treatment processes are required, various restrictions of the material of the film, the types of the substrates and film thickness so as to achieve high adhesion and high performance coating. This team realizes innovative improvement of materials, devices and products in a wide range of applied fields by aerosol deposition (AD) method and suspension plasma spraying method as core technologies, the former utilize ambient temperature impact solidification phenomenon and was discovered and developed at AIST.

<Research outline>

AD method

- Elucidation of consolidation and densification mechanism of ceramic powder at room temperature, and development to production technology

- Microstructural control (nanocrystal, nanoporous, nanocomposite, and fine inclined structure)

- Prototyping and principle verification for various device applications such as power device application, weight reduction of structural members , application of battery members by lamination, composite and porous structure, implant member application.

Suspension plasma spraying method

- Development of suspension plasma spraying method in which fine particles are introduced in the form of a suspension

- Control of microstructure from dense, uniform coating to cauliflower-like porous coating

- Applications for heavy industry such as heat shielding coating

Photo-assisted Coating Team

<Research outline>

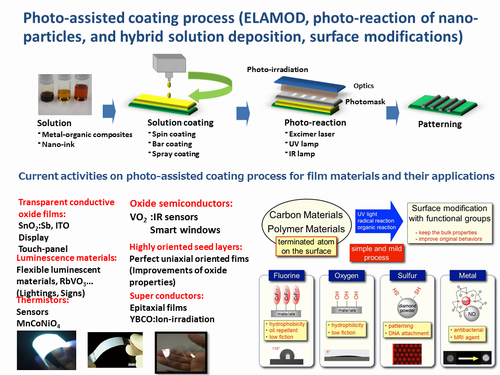

This team will develop photoreaction coating process of metals and metal oxides at low-temperature such as photo assisted MOD: ELAMOD and photoreaction of nanoparticle-contained hybrid solution to develop new materials and devices by the processes. Also it will develop photochemical surface modification method to induce various surface properties such as hydrophobic and hydrophilic. In addition, it will develop patterning of conductor with fine width and high aspect ratio by laser assisted Ink-Jet printing: LIJ.

<Research content>

- Development of novel coating technology using photoreaction

- Coating metal oxide material on plastic substrate in air, at low temperature and at high speed

- Synthesis of various phosphor materials (phosphorescence, white, suppressing plant germination, etc.)

- Development of hybrid coating solution using various materials

- Preparation of of epitaxial thin film in air at low temperature

- Fabrication and application of oriented films of various materials

- Photochemical surface modification method to induce various surface properties such as hydrophobic and hydrophilic

- Patterning of conductor with width of 10 μm or less and high aspect ratio (wiring thickness / wiring width) by LIJ

Energy Conversion and Storage Materials Team

<Research outline>

Lithium secondary batteries are expected to spread and expand in the future for automotive applications and large-scale applications such as stationary power supplies. For that purpose, safety improvement, longer life, further higher capacity and lower cost are key technologies.

In order to realize such next-generation storage batteries and fuel cells, we are developing new high-performance oxide materials and such as electrode and electrolyte materials and device fabrication using coating technology. In addition, we are developing new material design by exploiting new manufacturing process and applying accurate crystal structure analysis.

<Research Content>

- New manganese oxide positive electrode material with cobalt-free and high capacity exceeding 250 mAh/g

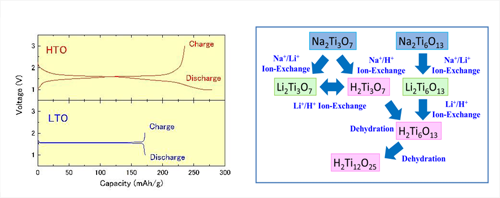

- A novel titanium oxide negative electrode (HTO) material with high capacity by about 40% compared with that of LTO

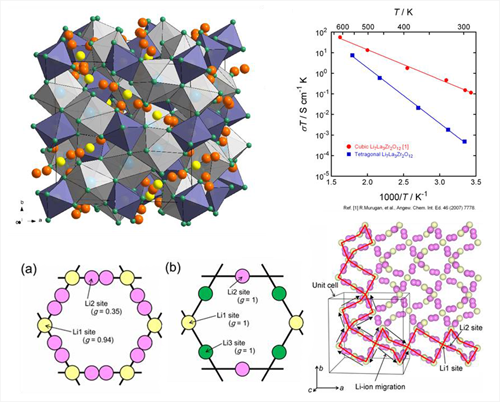

- Garnet-type oxide solid electrolyte material which can be applied to all-solid-state batteries and lithium-air batteries

- Development of high-performance materials and devices for energy conversion / storage applying coating technology such as AD

- Precise crystal structure analysis technique applying X-ray and neutron diffraction techniques and various electrochemical and physical measurements

Novel Titanium Oxide (HTO)

Green Device Materials Team

<Research outline>

The main targets of this team are smart windows, optical devices with a large market size, various sensors that are effective for light and energy consumption reduction, photoelectrode, energy harvesting by flexible piezoelectric coating. We will synthesize and analyze various materials for green devices, and develop the coating devices in cooperation with photo-assited coating team and fine powder spray coating team. We will aim for bridging the valley of death and rapid commercialization of these advanced materials and devices, through benchmarking and evaluation by collaboration with energy conversion and storage materials team and the coating alliance with upstream / downstream companies.

<Research Content>

- Development of green device materials by ultraviolet/infrared laser and lamp

- Development and coating of various phosphor materials (smart luminescence)

- Control of electrical and optical properties of oxide semiconductor

- Development of nanoparticle-containing hybrid coating solution

- Development of green device applying coating technology such as ELAMOD